WATER, FOOD & BEVERAGE

The water, food & beverage sectors demand the highest standards of hygiene, product purity, and regulatory compliance across all processing operations. Today’s food manufacturing, beverage production, and water processing facilities rely on precision-engineered components capable of meeting stringent sanitary requirements, industry standards & regulations, and maintaining product integrity throughout production. At LDR, we specialize in providing NSF-compliant pumps and sanitary filtration solutions that exceed the demanding requirements of hygienic process industries.

CRITICAL ENGINEERING SPECIFICATIONS FOR HYGIENIC PROCESSING EXCELLENCE

FDA and Sanitary Standards Compliance

Comprehensive compliance with FDA, 3-A Sanitary Standards, EHEDG, and USP Class VI requirements with complete validation documentation

Hygienic Design Principles

Smooth surfaces, crevice-free construction, and easy disassembly for thorough cleaning and sterilization procedures

Product Purity Assurance

Oil-free operation and contamination-free fluid handling maintaining product integrity and preventing cross-contamination

CIP/SIP Compatibility

Superior compatibility with cleaning chemicals, sanitizers, and aggressive process fluids used in food and beverage production

Chemical Resistance Excellence

Superior compatibility with cleaning chemicals, sanitizers, and aggressive process fluids used in food and beverage production

MISSION-CRITICAL SOLUTIONS: RAPID VALIDATION, HYGIENIC RELIABILITY, PRODUCT INTEGRITY

Our FDA-compliant pumps and sanitary filtration systems serve as essential components in food-grade processing operations, providing food and beverage manufacturers with rigorously tested, regulatory-compliant components precisely engineered for hygienic applications while ensuring product safety and quality.

KEY ADVANTAGES

Proven Hygienic Performance

FDA NSF-compliant pumps with demonstrated reliability in food processing environments, maintaining product purity with zero contamination incidents

Accelerated Regulatory Compliance

Pre-configured documentation packages optimized for FDA, 3-A, and EHEDG requirements, reducing validation timelines and regulatory approval processes

Enhanced Product Quality

Contamination-free operation preserving flavor profiles, nutritional content, and product characteristics throughout processing operations

Superior Total Cost of Ownership

Extended service life in harsh cleaning environments reducing replacement frequency and maintenance costs while maximizing production uptime

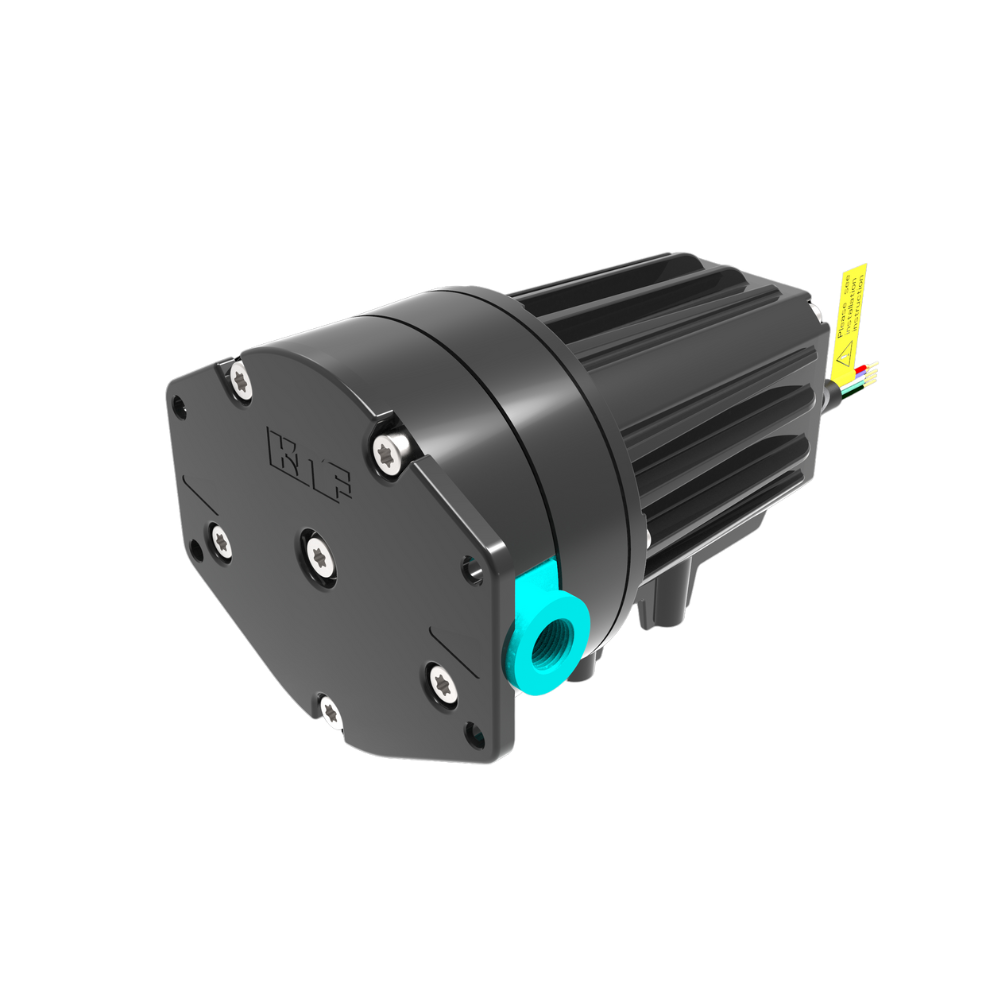

KNF FDA NSF-COMPLIANT DIAPHRAGM PUMPS FOR FOOD & BEVERAGE APPLICATIONS

KNF diaphragm pumps serve as critical components across diverse food and beverage applications, specifically engineered to meet the demanding hygienic requirements of the food processing industry with proven FDA compliance and sanitary design principles.

Food Processing and Manufacturing

Advanced pumping solutions for food production operations requiring absolute hygiene, gentle product handling, and regulatory compliance

Key Applications:

Ingredient Transfer

Gentle handling of sensitive ingredients, sauces, and liquid food products with flow rates up to 12 L/min

Flavor and Additive Dosing

Precision dosing pumps for flavoring systems, preservatives, and nutritional supplements

Dairy Processing

Hygienic transfer of milk, cream, yogurt, and dairy-based products maintaining product integrity

Sauce and Paste Handling

Viscous product transfer for condiments, pastes, and processed food applications

Beverage Production Operations

Reliable pumping solutions for beverage manufacturing requiring product purity, flavor preservation, and contamination prevention

Applications:

Brewery Operations

Specialized pumps for wort transfer, yeast handling, and beer processing with chemical resistance to cleaning agents

Wine Production

Gentle transfer systems for must, wine, and spirits preserving delicate flavor profiles

Soft Drink Manufacturing

Hygienic pumps for syrup handling, flavoring systems, and carbonated beverage production

Bottled Water Processing

Ultra-pure water transfer systems meeting stringent quality standards

PORVAIR FILTRATION SOLUTIONS FOR FOOD & BEVERAGE APPLICATIONS

Porvair filters provide mission-critical filtration solutions for food and beverage operations, engineered to exceed the demanding requirements of hygienic processing applications with proven FDA compliance and sanitary design principles.

Food and Beverage Processing Filtration Systems

FDA-Approved Membrane Filters

Disposable polymeric filters manufactured from FDA-approved materials under cleanroom conditions, meeting EC Directives for Food Contact with complete validation documentation

Bacterial Retention Filtration

Sterilizing grade membrane filters providing >10⁷ colony forming units retention per square centimeter of filtration area, fully validated according to PDA Technical Reports

Hygienic Stainless Steel Filters

Porous stainless steel cartridge filters complying with 3-A Standard 609-01 for culinary steam applications and high-temperature processing

COMPREHENSIVE FOOD & BEVERAGE FILTRATION PORTFOLIO

Beverage Production Filtration

Critical filtration solutions for alcoholic and non-alcoholic beverage production maintaining product quality and microbiological stability

Applications:

Wineries

Pre-filtration and microbiological stabilization for wine clarification and quality enhancement

Breweries

PVPP and DE particulate trap filtration, bio-burden reduction prior to pasteurization, and sterile CO₂ filtration

Cider Production

Pre-filtration and microbiological stabilization maintaining natural flavors and clarity

Spirits Manufacturing

Crystal clear product filtration removing particulates while preserving flavor characteristics

Soft Drinks

Microbial stabilization of water, particulate removal from sugar and flavorings, and sterile CO₂ filtration

Technical Features:

Microbial Stabilization

Effective removal of yeast, mold spores, and bacteria ensuring product shelf life

Particulate Control

Precise filtration removing unwanted particles while preserving product characteristics

Sterile Gas Filtration

CO₂ and nitrogen filtration for carbonation and packaging operations

Water Treatment

High-purity water filtration for beverage base preparation

Food Manufacturing Filtration

Advanced filtration solutions for food production including dairy, processed foods, and specialty applications

System Benefits:

Ingredient Purification

Removal of contaminants from raw materials and ingredients

Process Protection

Equipment protection preventing damage from particulate contamination

Quality Assurance

Final product filtration ensuring consistent quality and appearance

Regulatory Compliance

Meeting FDA and international food safety standards

Filtration Products for Water Processing Applications

A complete line filters and filter media used throughout the water treatment industries in a broad range of applications

Manufacturing Applications:

Desalination

for the reuse of seawater in industrial processes and even as drinking water.

Industrial water

- water treatment for applications such as beverage production, parts washing and paper production.

Irrigation

water reuse for landscaping and the growth of fresh crops.

Process and utilities water

- for use within manufacturing processes, general technical plants, cleaning, maintenance and engineering systems.

Waste water treatment

aeration for breaking down organic components of effluent and providing oxygen to feed aerobic bacterium that decomposes organic matter.

Municipal water

for the production of potable water.

Advanced Vyon® Porous Media Technology

Porvair's proprietary porous plastic media manufactured from USP Class VI approved materials, specifically suitable for food and pharmaceutical applications

Technical Features:

FDA Compliance

Manufactured from FDA-approved HDPE and PP materials meeting food contact requirements

Controlled Porosity

Uniform pore structure providing consistent filtration performance and flow characteristics

Chemical Compatibility

Broad resistance to cleaning chemicals, sanitizers, and process fluids

Cleanroom Manufacturing

Production in ISO-certified cleanrooms ensuring consistent quality and contamination control

Custom Fabrication

Tailored solutions from simple discs to complex 3D molded components

COMPREHENSIVE TECHNICAL SUPPORT & FOOD AND WATER INDUSTRY ENGINEERING

LDR’s food and beverage specialists provide comprehensive engineering support throughout the project lifecycle:

Regulatory Compliance Guidance

FDA, 3-A, EHEDG, and USDA certification support with complete documentation packages

Hygienic Design Consultation

Sanitary equipment selection based on cleaning requirements and contamination prevention

Material Selection

Food-grade material verification and chemical compatibility assessment for specific applications

Validation Support

HACCP documentation, cleaning validation protocols, and regulatory submission assistance

Process Optimization

Production efficiency analysis and equipment optimization for improved throughput and quality

Maintenance Planning

Sanitary maintenance procedures and component lifecycle management for food-grade equipment

CONTACT OURCONTACT OUR WATER, FOOD & BEVERAGE EXPERTS

Have specific challenges in food processing or beverage production requiring FDA-compliant pumps and sanitary filtration solutions? Our engineering team collaborates directly with KNF and Porvair food industry specialists to develop optimal solutions for your hygienic processing operations.