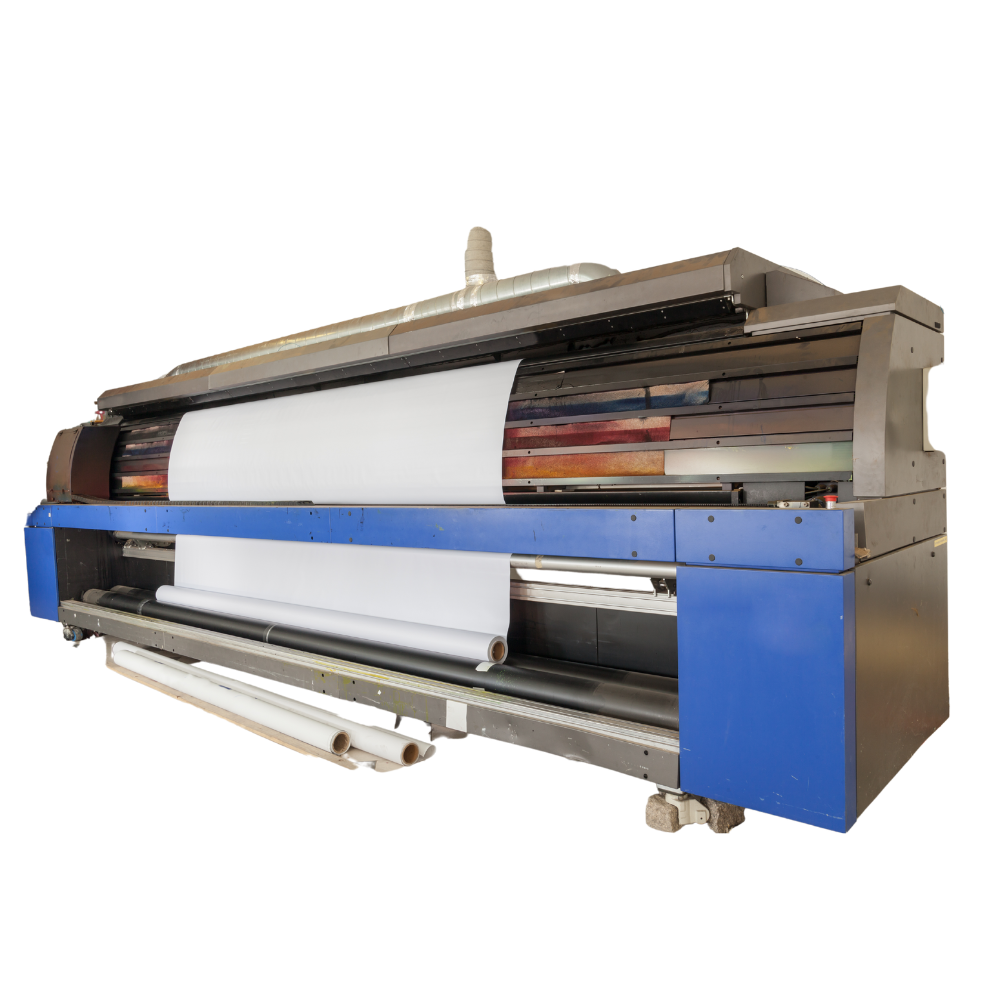

DIGITAL PRINTING

The digital printing industry continues to evolve rapidly, extending far beyond traditional paper applications into diverse sectors including textiles, ceramics, glass, electronics, and additive manufacturing. Today’s advanced inkjet systems demand precision-engineered components that ensure consistent performance, superior print quality, and operational reliability across demanding production environments.

MISSION-CRITICAL ENGINEERING CHALLENGES IN DIGITAL INKJET SYSTEMS

Precision Ink Flow Control

Absolute flow consistency without pulsation or pressure fluctuations that compromise print quality and damage sensitive printheads

Aggressive and Abrasive Media Handling

Compatibility with challenging ink formulations including pigmented, UV-curable, solvent-based, and chemically aggressive fluids

Critical Printhead Protection

Safeguarding expensive, precision-engineered printheads from contamination, pressure spikes, and particulate damage

Space-Constrained Integration

Compact, modular solutions designed for seamless integration within existing printer architectures

Continuous Production Reliability

Systems engineered for sustained operation with minimal maintenance requirements and maximum uptime

PRECISION-ENGINEERED SOLUTIONS FOR INKJET EXCELLENCE

LDR’s comprehensive understanding of digital printing challenges drives our selection of KNF diaphragm pumps and Porvair filtration systems. This synergistic combination enables inkjet systems to achieve optimal performance, ensuring superior print quality and extended operational life across diverse applications.

KEY ADVANTAGES

Enhanced Print Quality Assurance

Smooth, contamination-free ink delivery ensuring consistent droplet formation and precise color reproduction

Extended System Component Life

Comprehensive protection of valuable printheads, pump components, and fluid delivery systems against premature wear

Maximized Production Uptime

High-reliability components designed for continuous operation with predictable maintenance intervals

Operational Cost Optimization

Reduced ink waste, minimized maintenance requirements, and superior energy efficiency for improved profitability

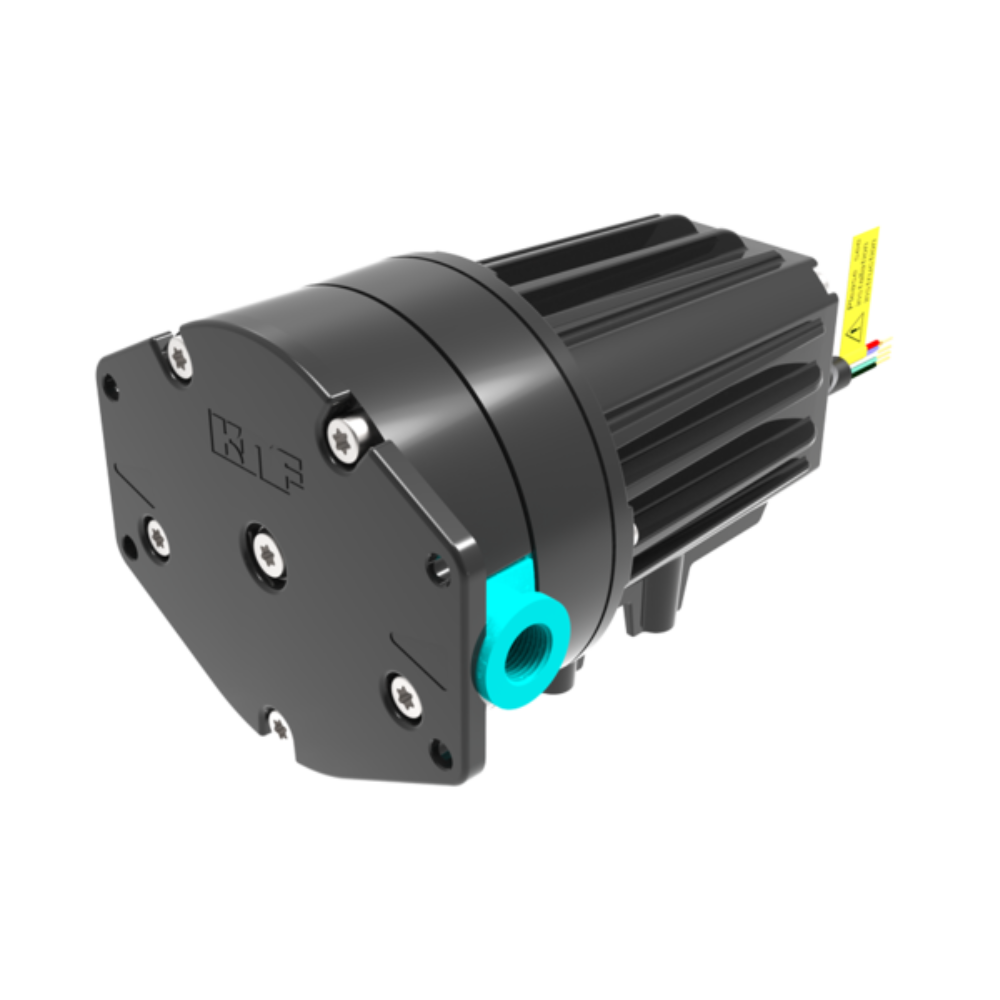

KNF SMOOTH FLOW TECHNOLOGY FOR DIGITAL PRINTING

Revolutionary Low-Pulsation Pump Technology

KNF Smooth Flow diaphragm pumps deliver exceptional ink flow consistency with minimal pulsation, revolutionizing fluid handling in demanding inkjet applications

Integrated Pulsation Dampening

Built-in dampers providing smooth, low-pulsation flow eliminating need for external dampening systems

Flow Resistance Reduction

Up to 70% decrease in resistance through micro-bore tubing, enabling efficient transfer of high-viscosity inks up to 500 cP

Shear Force Minimization

85% reduction in shear forces protecting sensitive pigments, emulsions, and functional particles

Pressure Peak Elimination

Smooth flow characteristics preventing ink foaming, pre-curing, and printhead damage

Drop-on-Demand (DOD) Applications

Advanced diaphragm pumps specifically engineered for precision droplet formation and printhead control

Negative Pressure Control

Precise meniscus management at printhead nozzles for optimal droplet formation

Ink Supply Systems

Consistent, low-pulsation ink delivery maintaining printhead pressure specifications

Cleaning and Maintenance

Dedicated pumps for printhead purging and maintenance operations

Recirculation Systems

Complex ink circulation maintaining fluid properties and preventing settling

PORVAIR PRECISION FILTRATION FOR INKJET APPLICATIONS

Porvair's comprehensive range of filtration solutions specifically designed for digital printing applications, ensuring contamination-free ink delivery and optimal print quality

Precision Particle Removal

Filtration grades from 0.5 to 70 microns for precise contamination control

Filters preventing clogs in delicate print head nozzles

Chemical Compatibility

Filters resistant to aggressive solvents, UV inks, and aqueous formulations

Minimal Extractables

Inert construction materials preventing ink contamination and maintaining fluid properties

Superior Flow Characteristics

Optimized geometry ensuring minimal pressure drop and consistent performance

TECHNICAL SUPPORT & APPLICATION ENGINEERING

LDR’s digital printing specialists provide comprehensive technical guidance:

System Design Consultation

Application-specific pump and filter selection based on ink properties and system requirements

Flow Analysis

Pressure drop calculations and system optimization for optimal performance

Material Compatibility Assessment

Chemical resistance verification and material selection guidance

Integration Support

Technical assistance for component integration and system commissioning

Performance Optimization

Troubleshooting and system enhancement for improved efficiency and quality

Maintenance Planning

Preventive maintenance programs and component lifecycle management

CONTACT OUR DIGITAL PRINTING EXPERTS

Have specific challenges in digital printing applications? Our engineering team collaborates directly with KNF and Porvair technical specialists to develop optimal fluid handling and filtration solutions for your demanding printing requirements.