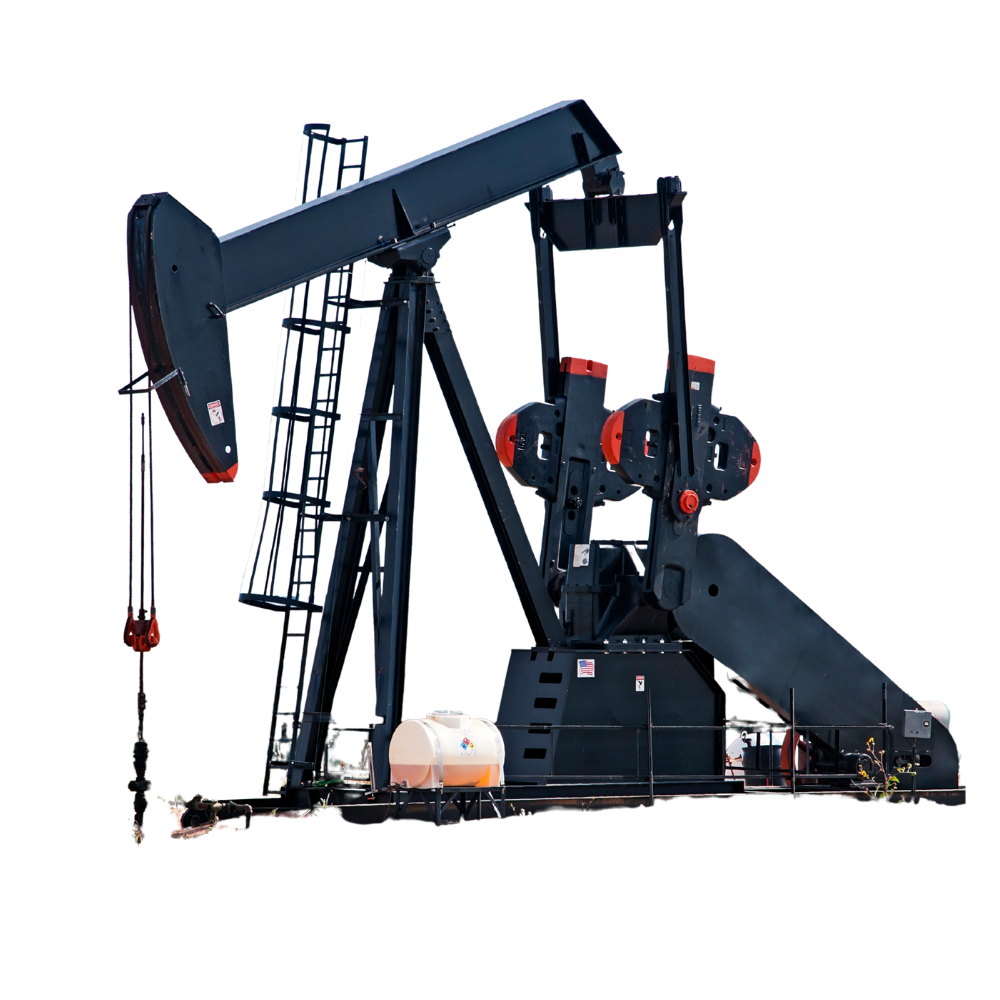

ENERGY & PETROCHEMICAL

The oil, gas, and petrochemical industries operate in some of the most demanding and hazardous environments requiring absolute reliability, explosion-proof equipment, and chemical resistance. Today’s upstream, midstream, and downstream operations depend on precision-engineered components capable of handling aggressive media, extreme temperatures, and safety-critical applications. At LDR, we specialize in providing explosion-proof pumps and high-performance filtration solutions that meet the stringent requirements of the energy and petrochemical sectors.

CRITICAL ENGINEERING SPECIFICATIONS FOR HAZARDOUS LOCATION EXCELLENCE

Explosion-Proof Certification Compliance

Comprehensive ATEX and NEC Class 1 Division 1 certification with UL and CSA approved motors for safe operation in hazardous locations

Chemical Resistance Assurance

Superior compatibility with aggressive hydrocarbons, corrosive gases, and petrochemical process fluids with specialized wetted material selection

High-Temperature Operation

Proven performance in extreme temperature environments from cryogenic applications to high-temperature process conditions

Zero Contamination Requirements

Oil-free operation preventing product contamination and maintaining process purity in sensitive refining operations

Robust Industrial Design

Heavy-duty construction engineered for continuous operation in harsh offshore, refinery, and chemical processing environments

MISSION-CRITICAL SOLUTIONS: PROVEN SAFETY, EXTENDED RELIABILITY, CONTAMINATION-FREE OPERATION

Our explosion-proof pumps and specialized filtration systems serve as essential components in safety-critical petrochemical operations, providing energy sector manufacturers with rigorously tested, hazardous location certified components precisely engineered for demanding applications while ensuring operational safety and reliability.

KEY ADVANTAGES

Proven Hazardous Location Performance

Explosion-proof pumps with demonstrated reliability in Class 1 Division 1 environments, handling dangerous and expensive media with zero safety incidents

Enhanced Process Reliability

Contamination-free operation maintaining product quality throughout refining, processing, and distribution operations with minimal maintenance requirements

Operational Cost Optimization

Extended service life in corrosive environments reducing replacement frequency and maintenance costs while maximizing process uptime

Comprehensive Safety Compliance

Full documentation packages for hazardous location installations meeting international safety standards and regulatory requirements

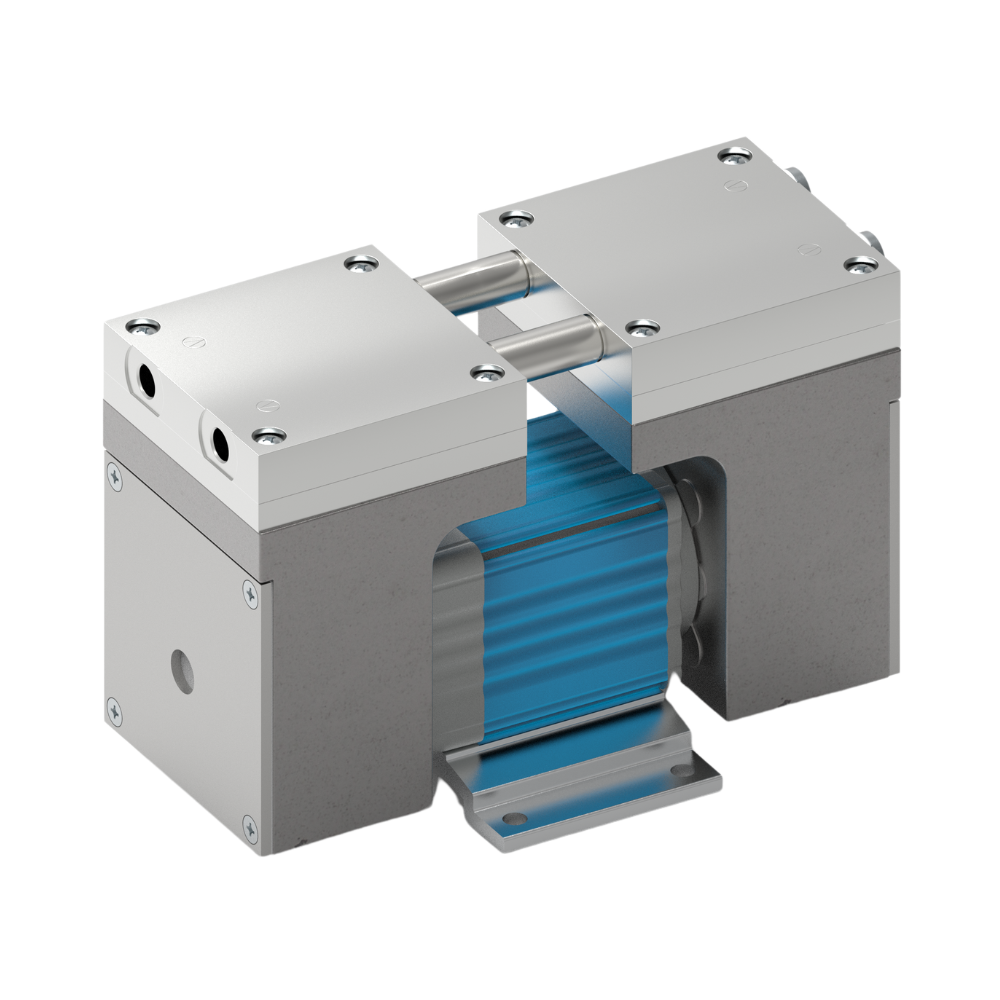

KNF DIAPHRAGM PUMPS FOR PETROCHEMICAL APPLICATIONS

KNF explosion-proof diaphragm pumps serve as critical components across diverse petrochemical applications, specifically engineered to meet the demanding safety and performance requirements of hazardous location operations with proven ATEX and NEC certification.

Upstream Oil & Gas Operations

Advanced pumping solutions for exploration, drilling, and production operations requiring explosion-proof certification and chemical resistance

Key Applications:

Gas Sampling Systems

Explosion-proof gas pumps for natural gas analysis and composition monitoring with flow rates up to 300 L/min

Process Monitoring

Chemical-resistant pumps for hydrocarbon transfer and analysis equipment in hazardous locations

Well Testing

High-pressure pumps capable of handling aggressive drilling fluids and completion chemicals

Emissions Monitoring

Specialized pumps for stack gas analysis and environmental compliance measurement

Midstream Processing Equipment

Reliable pumping solutions for pipeline operations, gas processing, and petrochemical manufacturing requiring safety-critical performance

Applications:

Pipeline Sampling

Explosion-proof pumps for continuous hydrocarbon sampling and quality control monitoring

Gas Processing

Chemical transfer pumps for amine systems, glycol dehydration, and acid gas removal processes

Vapor Recovery

Vacuum pumps for vapor collection and recovery systems in storage and loading operations

Process Analytics

Precision pumps for chromatography and analytical instrumentation in process control

Downstream Refining Operations

High-performance pumps designed for refinery operations including distillation, cracking, and petrochemical production processes

Technical Applications:

Catalyst Handling

Chemical-resistant pumps for catalyst preparation and circulation in refining processes

Additive Injection

Precision dosing pumps for fuel additives, antioxidants, and performance enhancers

Laboratory Analysis

Analytical pumps for fuel quality testing and petrochemical characterization

Waste Treatment

Pumps for wastewater processing and environmental remediation systems

Advanced Explosion-Proof Technology

KNF explosion-proof pumps feature specialized design elements ensuring safe operation in hazardous environments while maintaining superior performance

Safety Performance Features:

ATEX and NEC Certification

Class 1 Division 1 Groups C & D, and Division 2 Groups A, B, C, D compliance

Minimized Power Requirements

Reduced electrical consumption lowering spark and overheating risks

Double Safety Diaphragms

Backup diaphragm system preventing dangerous media leakage in primary diaphragm failure

Gas-Tight Operation

Superior sealing preventing hazardous gas accumulation and explosion risks

Chemical Compatibility

Specialized wetted materials resistant to hydrocarbons, acids, and corrosive process fluids

Temperature Resistance

Operation capability from cryogenic conditions to high-temperature process environments

PORVAIR FILTRATION SOLUTIONS FOR PETROCHEMICAL APPLICATIONS

Porvair filters provide mission-critical filtration solutions for oil, gas, and petrochemical operations, engineered to exceed the demanding requirements of hazardous location applications with proven performance in extreme conditions.

Hydrocarbon Processing Filtration Systems

High-Temperature Metal Filters

Sinterflo® metal filtration systems manufactured from 316L stainless steel and exotic alloys, designed for extreme petrochemical processing conditions with operating temperatures up to 540°C

Chemical-Resistant Filtration

Specialized filtration media resistant to aggressive hydrocarbons, organic solvents, and corrosive process chemicals throughout the petrochemical value chain

High-Pressure Applications

Robust filter construction capable of withstanding high differential pressures and extreme operating conditions in refinery and chemical processing operations

COMPREHENSIVE PETROCHEMICAL FILTRATION PORTFOLIO

Refinery Process Filtration

Critical point-of-use protection for catalysts, additives, and finished products throughout the refining process

Applications:

Fuel Quality Control

Final filtration of gasoline, diesel, jet fuel, and kerosene prior to distribution

Catalyst Protection

Pre-filtration systems protecting expensive catalysts from contamination and poisoning

Additive Injection

Precision filtration for fuel additives, antioxidants, and performance enhancement chemicals

Wastewater Treatment

Specialized filters for refinery wastewater processing and environmental compliance

Technical Features:

Contamination Removal

Effective elimination of rust, particles, and debris from stored petroleum products

Water Separation

Coalescing filters for water removal from hydrocarbon streams

Multi-Stage Filtration

Series filtration systems for progressive contamination control

High Flow Capacity

Large-scale filtration systems for bulk petroleum product processing

Gas Processing Filtration

Advanced filtration solutions for natural gas processing, LNG operations, and petrochemical gas handling

System Benefits:

Corrosion Protection

Removal of corrosive contaminants protecting downstream equipment

Product Purity

Maintaining gas quality specifications for commercial and industrial applications

Equipment Protection

Preventing damage to compressors, heat exchangers, and process equipment

Environmental Compliance

Meeting emission standards and regulatory requirements

Chemical Manufacturing Filtration

Specialized solutions for petrochemical production including polymers, plastics, and specialty chemicals

Manufacturing Applications:

Polymer Production

Filtration systems for polyethylene, polypropylene, and specialty polymer manufacturing

Catalyst Recovery

Filter systems for catalyst separation and recovery in chemical processes

Solvent Purification

High-purity filtration for organic solvents and chemical intermediates

Final Product Quality

Point-of-use filtration ensuring finished product

Advanced Sinterflo® Metal Technology

Porvair's proprietary sintered metal filtration media engineered for the most demanding petrochemical applications

Technical Features:

Extreme Temperature Resistance

Operating capability from cryogenic to 1000°C in specialized applications

Chemical Inertness

Broad compatibility with hydrocarbons, acids, bases, and organic solvents

Mechanical Strength

Superior structural integrity under high differential pressures and thermal cycling

Cleanability

In-situ cleaning capability extending filter life and reducing operating costs

Custom Fabrication

Tailored solutions from single elements to complete vessel assemblies

COMPREHENSIVE TECHNICAL SUPPORT & PETROCHEMICAL ENGINEERING

LDR’s petrochemical specialists provide comprehensive engineering support throughout the project lifecycle:

Hazardous Location Compliance

ATEX, NEC, and international explosion-proof certification guidance and documentation

Application Engineering

Equipment selection based on process conditions, chemical compatibility, and safety requirements

Material Selection

Chemical resistance verification and wetted material selection for specific hydrocarbon applications

Safety System Design

Integration support for safety instrumented systems and emergency shutdown procedures

Performance Optimization

Process analysis and equipment optimization for improved efficiency and reliability

Maintenance Planning

Predictive maintenance programs and component lifecycle management for hazardous location equipment

CONTACT OUR PETROCHEMICAL EXPERTS

Have specific challenges in oil, gas, or petrochemical applications requiring explosion-proof pumps and specialized filtration solutions? Our engineering team collaborates directly with KNF and Porvair petrochemical specialists to develop optimal solutions for your safety-critical operations.