DEFENCE & AEROSPACE

The defence and aerospace industries impose extreme demands on components and systems. Aircraft, satellites, naval vessels, and advanced defense equipment rely on components that must operate under the most challenging environmental conditions – from extreme temperatures and vibrations to pressure variations and radiation exposure. In these environments, reliability and precision are not just desirable – they are essential for safety, mission success, and national security.

CRITICAL CHALLENGES IN THESE APPLICATIONS

Extreme Environmental Durability

Operating temperatures up to +240°C, and sudden pressure changes

Absolute Reliability

Zero tolerance for failure in mission-critical and safety-critical systems

Minimal Weight Requirements

Every gram affects performance, range, and fuel consumption in aerospace and space systems

Energy Efficiency

In battery-powered or space systems, every watt is critical to mission success

Specialized Fuel and Fluid Compatibility

Resistance to military fuels, hydraulic fluids, and other corrosive specialized fluids

OUR SOLUTIONS - PROVEN ADVANTAGES FOR DEFENCE AND AEROSPACE SYSTEMS

Over two decades, our engineering team has worked on defence and aerospace projects where failure is not an option. From this experience, we have developed unique capabilities to identify and implement pumping and filtration solutions that combine lightweight design, extreme condition reliability, and exceptional service life – the three keys to success in critical systems.

KEY ADVANTAGES

Proven Reliability in Critical Missions

Solutions tested under the most demanding real-world conditions – from operational UAVs and fighter aircraft to satellites. Our systems demonstrate failure rates below 0.05% and meet MIL-STD-810G and DO-160G standards.

Critical Weight Reduction for Performance

Advanced material solutions saving tens of percent in weight. In airborne systems, this translates to improved operational range, fuel savings, and ability to carry additional equipment.

Exceptional Service Life in Extreme Environments

Components designed for 20,000+ hours of maintenance-free operation. Filters maintaining 98% of filtration capacity even after hundreds of extreme temperature cycles.

Rapid Integration for Risk Minimization

Standard interfaces and comprehensive engineering documentation reducing integration time by 60%. Support for RS-485, CAN, and MIL-STD-1553B protocols for rapid connection and reduced development risks.

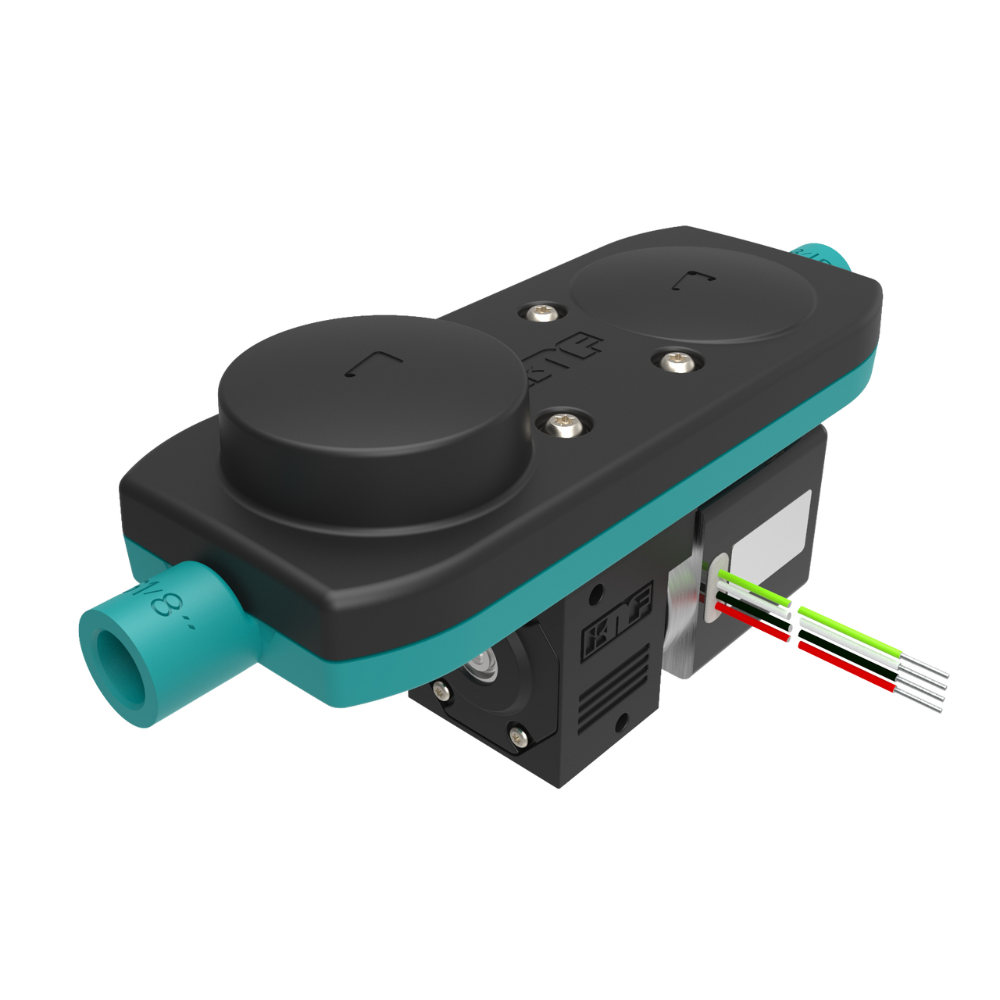

KNF PUMPS FOR DEFENCE & AEROSPACE, INDUSTRIES

KNF pumps form the technological core of critical defence and aerospace systems, from advanced weapon systems to fighter aircraft and UAVs. Each pump undergoes unique hardening processes, enabling control of liquids, gases, and vacuum under conditions of severe vibrations, varying pressures, and extreme temperatures.

Extreme Temperature Resistance in Operational Environments

Reliable operation across temperature ranges up to 240°C, including resistance to sharp temperature transitions. Passive thermal balancing technology enables pumps to operate stably even with temperature changes of 100°C+ in short time periods, critical in avionics and weapon systems.

Sealing and Electromagnetic Isolation

Sealing ratings above IP65, with advanced EMI/EMC electromagnetic shielding according to MIL-SPEC standards. Mechanisms for protection from electromagnetic fields and electronic attacks, essential in electronic warfare environments.

Advanced Protection Technologies

Specialized coatings and materials resistant to military chemicals, jet fuels, hydraulic fluids, and oxidizing materials. Multi-layer protection according to MIL-SPEC specifications and NATO standards, ensuring reliability even under combat and extreme weather conditions.

Performance at Altitude and Variable Pressures

Proven operation under low pressure conditions at altitudes up to 60,000 feet and rapid pressure changes typical of flight maneuvers. Special materials and design ensuring reliability even in high humidity and saline environments in naval and coastal systems.

ADVANCED TECHNOLOGIES FOR CRITICAL APPLICATIONS

Our solutions are precisely tailored to meet the demanding requirements of defence systems, military aviation platforms, and advanced aeronautical applications.

Lightweight Pumps for Aviation Platforms

- Minimum weight pumps (starting from 80 grams) improving system power-to-weight ratio

Compact design from advanced materials: aeronautical aluminum and specialized alloys

- 60% reduced power consumption compared to traditional pumps, critical for autonomous airborne systems

- Installation configurations adapted to space constraints of avionics compartments and weapon system housings

Pumps for Military Fuels and Fluids

- Proven chemical compatibility with jet fuel (JP-8/JP-5), hydraulic fluids (Skydrol), and military fire retardants

- ATEX certifications and explosion-proof solutions for pumps in fuel and ammunition environments

- Oil-free operation preventing contamination of sensors and sensitive optical systems in intelligence and surveillance platforms

- Self-priming capability up to 8.5 meters, ideal for field refueling and emergency pumps in aircraft and armored vehicles

Specialized Solutions for Weapon Systems and Fire Control

- Pumps capable of operating at variable installation angles, essential for adjustable weapon systems

- Liquid cooling systems for radars and electro-optical systems with precise temperature control

- Vacuum solutions for stabilization systems, recoil braking, and ordnance cooling

- Specialized pumps for NBC systems and protection against chemical/biological warfare

Solutions for Avionics and Aeronautical Instrumentation

- Pressure control pumps for cockpit systems, avionics, and aerial navigation systems

- Air sampling systems for warning and protection systems against chemical and biological threats

- Vacuum solutions for sensor systems, gyroscopes, and aerial instrumentation equipment

- Precision pumps for calibration and pressure monitoring systems in propulsion and hydraulic systems

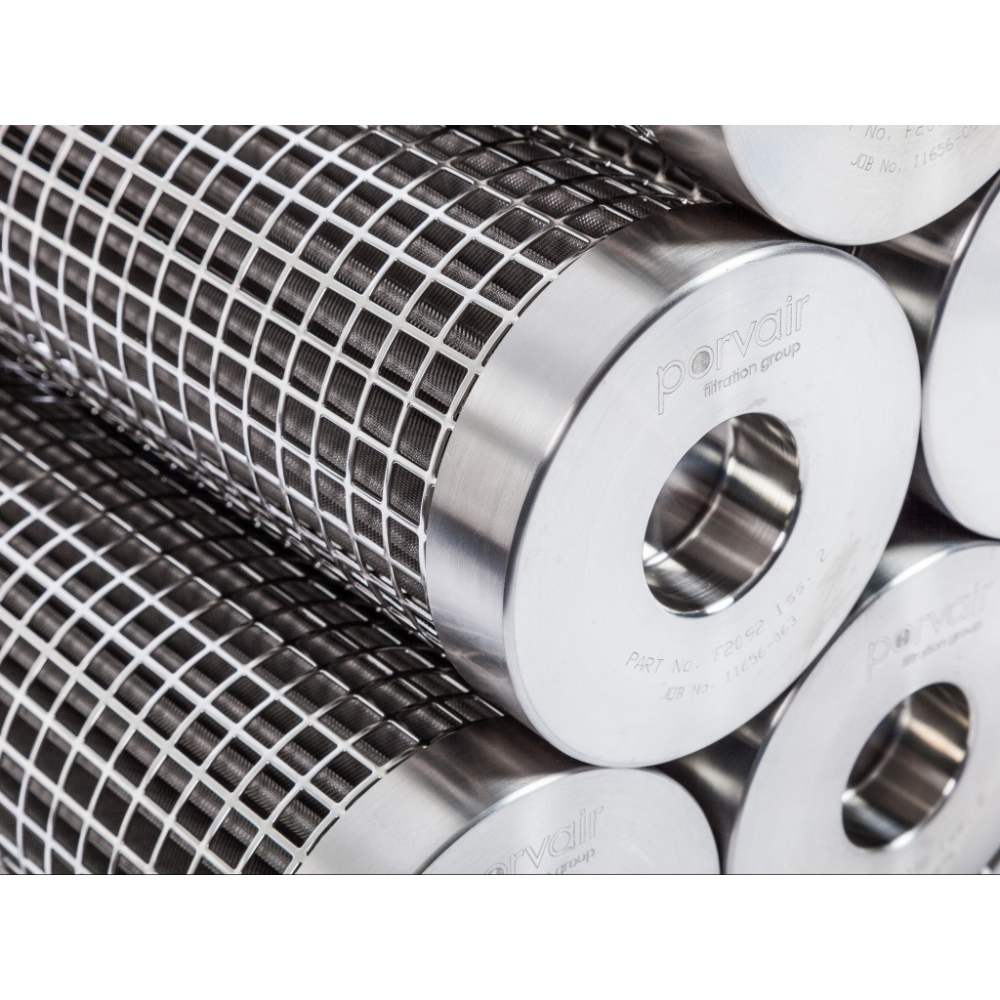

PORVAIR FILTERS FOR DEFENCE AND AEROSPACE INDUSTRIES

Porvair filters provide critical filtration solutions for defence and aerospace systems where reliability and precision are operational requirements.

Fuel and Oil Filters for Aerospace Systems

Jet fuel filters meeting military standards with 99.9% water separation capability

- Engine oil filters for fighter aircraft and helicopters, removing particles with 99.99% accuracy down to 3 microns

Aeronautical hydraulic filters resistant to very high pressures

- Filtration solutions for specialized military fuels and fuel additives used in advanced platforms

Protection Filters for Weapon and Propulsion Systems

- Aerosol filters for dusty and contaminated air environments in combat vehicle systems and weapon systems

- Metal particle capture filters for engine oil and hydraulic systems, extending system life

- Specialized pre-filters for protecting fuel and oil systems in extreme environment operations (desert, maritime terrain)

- Exhaust gas filtration solutions for propulsion systems, reducing platform thermal signature

Air and Atmospheric Filters

Air filters for crew compartments providing clean air free from particles and toxic gases

Breathing system and CBRN mask filters to MIL-SPEC standards

- Specialized environmental filters for sensitive electronic systems and advanced sensors

COMPREHENSIVE TECHNICAL SUPPORT & DEFENCE ENGINEERING

LDR’s defence and aerospace specialists provide comprehensive professional support:

Advanced Defence Consulting

Support for sensitive defence projects, including appropriate security classification

Military and Aerospace Standards Support

Compliance with MIL-STD, DO-160, AS9100, and other standards

Custom Development

Mission-specific requirements development

Full Lifecycle Support

Complete lifecycle support for defense and aerospace projects

Rapid Service for Critical Missions

Emergency support for urgent operational needs

CONTACT OUR DEFENCE & AEROSPACE EXPERTS

Have specific challenges in defence or aerospace applications requiring mission-critical pumps and specialized filtration solutions?

Our engineering team collaborates directly with KNF and Porvair defense specialists to develop optimal solutions for your critical operations.