KNF pumps are globally recognized for their exceptional reliability, meticulous German-Swiss quality, and precision-engineered solutions. As KNF’s official representatives in Israel, LDR delivers cutting-edge pumping technologies to the local market, backed by professional engineering consultation and comprehensive technical support.

Beyond standard pumps, KNF specializes in developing and adapting pumps for specific requirements through unique modular designs. LDR’s engineering team collaborates with KNF engineers to create solutions precisely tailored to your application parameters.

Advanced construction materials for handling aggressive chemicals or operating in extreme environmental conditions

Diaphragm pumps with flow rates from 0.018 to 250 l/min and operating pressures up to 16 bar, with precise flow control according to application-specific requirements

A wide range of DC and AC motors with digital control capabilities, achieving operational lifetimes exceeding 20,000 hours with customizable performance characteristics

Customized pneumatic/hydraulic connections and additional electrical interfaces for seamless and rapid integration into your final system

75+ years of experience and development based on continuous research, leading to innovative pump solutions

Proven reliability with thousands of hours of continuous operation in demanding environments, with minimal failure rates

Precise German-Swiss engineering ensuring accuracy, stability, and energy efficiency

Local engineering support from LDR's team in collaboration with KNF experts and precise adaptation to the specific requirements of your industrial application

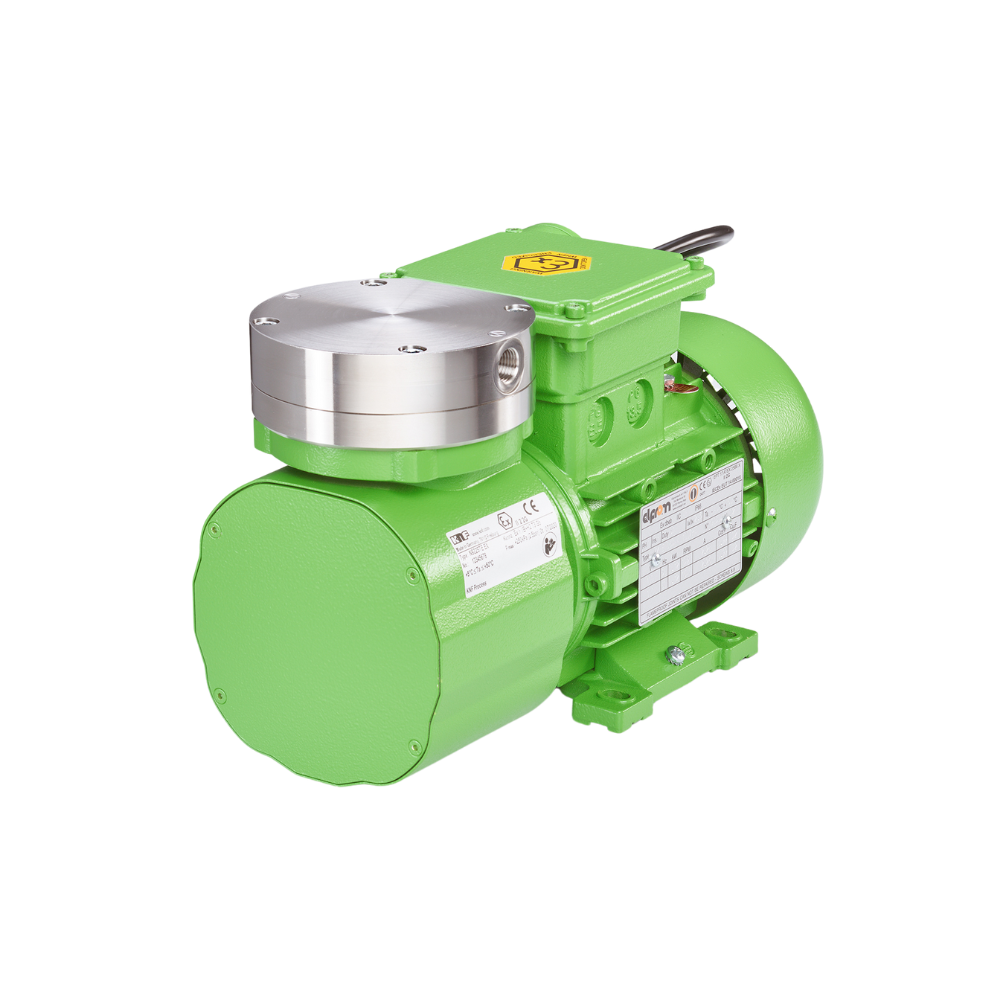

Pumps based on diaphragm technology for extraction and transfer of gases and air, with emphasis on oil-free and contaminant-free operation.

Oil-free operation – preventing gas contamination

High reliability with minimal maintenance

Options for various flow rates and pressures

Quiet operation with low vibration levels

Precision pumps for fluid transfer and regulation, enabling accurate flow rate control and prevention of liquid contamination.

Defence and security applications for trace detection

High accuracy at small and medium flow rates

Excellent chemical resistance

Dry-run capability without damage

Extended service life

Precision pumps for fluid transfer and regulation, enabling accurate flow rate control and prevention of liquid contamination.

Defence and security applications for trace detection

High accuracy at small and medium flow rates

Excellent chemical resistance

Dry-run capability without damage

Extended service life

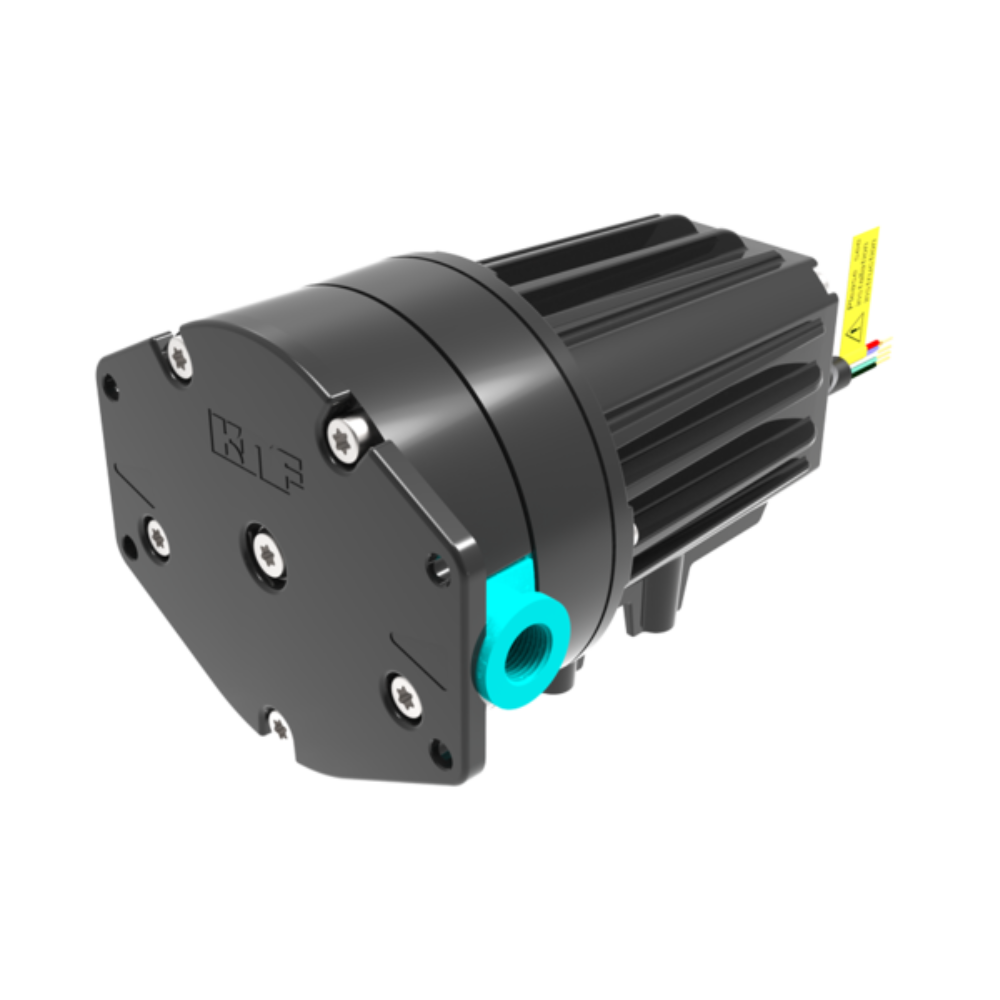

Compact to miniature gas and air pumps delivering high precision and quality for pressure or vacuum applications. Specifically designed for integration in space-constrained systems where standard-sized pumps cannot be accommodated.

Miniature dimensions with ultra-low power consumption

Low noise operation

Portable device compatibility

Extensive customization options for specific requirements

Engineered for vacuum generation or compression and pressure production. These pumps deliver higher flow rates than comparable diaphragm pumps while generating deep suction and high compression relative to their compact dimensions.

Oil-free operation

High flow rates

Superior performance-to-size ratio

Engineered for vacuum generation or compression and pressure production. These pumps deliver higher flow rates than comparable diaphragm pumps while generating deep suction and high compression relative to their compact dimensions.

Oil-free operation

High flow rates

Superior performance-to-size ratio

LDR’s diaphragm pump specialists provide comprehensive technical guidance:

Consultation and guidance for optimal pump selection

Technical support and troubleshooting

Professional maintenance and repair services

Genuine replacement parts

Technical training and implementation support

LDR specializes in supplying advanced pumps and filtration systems to various industrial sectors, operating in Israel since 2003. As official representatives of world-leading manufacturers, we provide high-quality pumps and filters tailored to a wide range of industrial needs, demonstrating a profound understanding of specific application requirements and budget constraints.

Crafted with BlogAbout