Porvair Filtration Group stands among the global leaders in developing and manufacturing high-performance filtration and separation solutions using innovative materials for mission-critical environments. As Porvair’s official representatives in Israel, LDR provides clients with access to cutting-edge filtration technologies designed for diverse industries and demanding applications. All filtration products are meticulously engineered to exceed the most stringent standards and deliver optimal separation performance.

Porvair filters represent the forefront of industrial filtration technology, developed through nearly 50 years of continuous innovation in materials science, manufacturing processes, and advanced engineering design. These filtration systems deliver reliable performance even in the most challenging industrial environments, backed by comprehensive regulatory compliance and technical documentation.

Utilizing proprietary membrane technologies and specialized materials enabling precise separation with superior efficiency

Filters engineered for continuous operation in high temperatures, elevated pressures, and aggressive chemical environments

Filter structure and filtration geometry optimized for maximum contaminant capacity and prevention of premature clogging

Available in multiple sizes, connection types, and configurations enabling precise integration with existing systems

Continuous development of proprietary filtration materials and advanced manufacturing technologies enabling high selectivity in particle and contaminant separation

Filters meeting the most stringent regulatory requirements in controlled industries, with comprehensive regulatory approvals that streamline validation processes

Precise optimization of filtration characteristics according to specific process requirements, including geometric, material, and functional adaptations

Consistent filtration performance over time under diverse challenging operating conditions, supported by thousands of installations in industries demanding the highest standards

Filters designed to remove particles, contaminants, and microorganisms from various liquids, ranging from water to aggressive chemicals and complex mixtures.

Filtration capability at multiple precision levels (0.1-100 microns)

Superior resistance to aggressive chemicals

Diverse construction material options

Filters for removing particles, aerosols, and other contaminants from process gas streams. Suitable for clean manufacturing environments, exhaust systems, and gas purification processes.

High filtration efficiency for particles and aerosols

Adaptability to various flow rates and pressures

Resistance to high temperatures

Filters for removing particles, aerosols, and other contaminants from process gas streams. Suitable for clean manufacturing environments, exhaust systems, and gas purification processes.

High filtration efficiency for particles and aerosols

Adaptability to various flow rates and pressures

Resistance to high temperatures

Disposable polymer cartridge filters customized for various industries

Diverse material options

Connections, lengths, and configurations for any requirement

Single-use design

Filtration capability at multiple precision levels (0.1-105 microns)

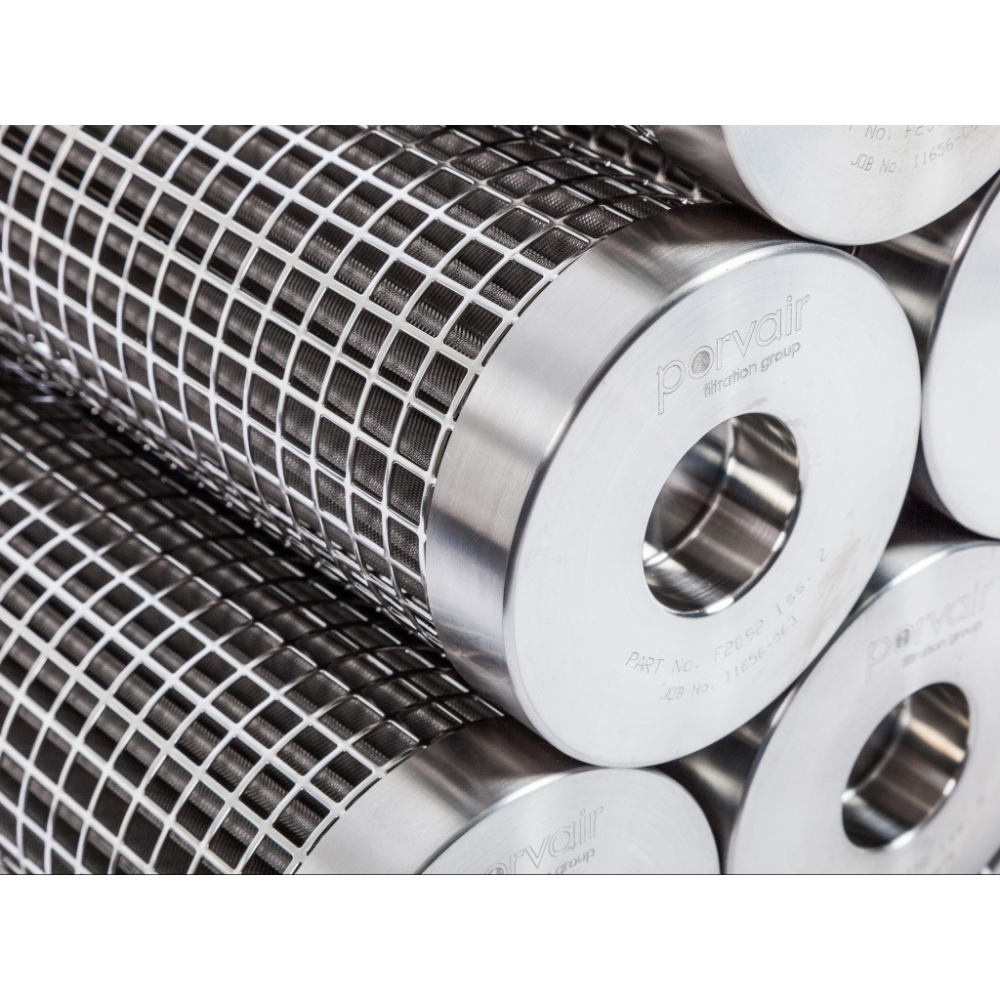

Sinterflo® metal filtration systems designed for extreme conditions in demanding industrial environments

Exceptional resistance to extreme temperatures (-269°C to 1000°C)

High-pressure tolerance capability

Cleanable and reusable design

Sinterflo® metal filtration systems designed for extreme conditions in demanding industrial environments

Exceptional resistance to extreme temperatures (-269°C to 1000°C)

High-pressure tolerance capability

Cleanable and reusable design

Ready-to-use disposable capsule filters with integrated housing for immediate installation without external components

Wide range of sizes, materials, and connections

White/transparent or UV-protected black capsules available

Filtration capability at multiple precision levels (0.03-150 microns)

Last chance filters complement main system filters in the digital printing industry. They remove contaminants such as chips, crystals, and liquid degradation products resulting from system processes or accumulating in fluids after primary filters

Various sizes and connections available

Customizable to client system dimensions and configuration

Available in metal or plastic designs

Last chance filters complement main system filters in the digital printing industry. They remove contaminants such as chips, crystals, and liquid degradation products resulting from system processes or accumulating in fluids after primary filters

Various sizes and connections available

Customizable to client system dimensions and configuration

Available in metal or plastic designs

LDR’s filtration specialists provide comprehensive technical expertise:

Professional consultation in selecting the appropriate solution

Analysis of filtration requirements and process parameters

Support in design and integration of filtration systems

Troubleshooting and optimization of existing filtration processes

Custom filter design services

LDR specializes in supplying advanced pumps and filtration systems to various industrial sectors, operating in Israel since 2003. As official representatives of world-leading manufacturers, we provide high-quality pumps and filters tailored to a wide range of industrial needs, demonstrating a profound understanding of specific application requirements and budget constraints.

Crafted with BlogAbout